Choose Material

- Share

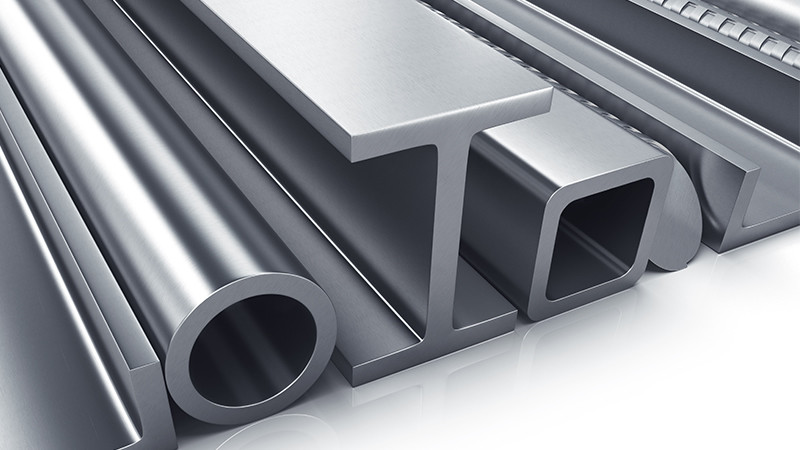

Material

In order to make it easier for customers to understand what kind of materials their products need, TERADA hardware has specially arranged several commonly used materials, showing their characteristics and advantages, so that you can choose the material that suits your needs.

Stainless Steel Material

Stainless steel (Stainless Steel) is an abbreviation for stainless acid-resistant steel. Steels that are resistant to weakly corrosive media such as air, steam, and water, or stainless steel are called stainless steel. The type of steel that is corroded is called acid-resistant steel.

Stainless Steel have SS201, SS303, SS304, SS316, SS316L and so on. Stainless steel is also divided into martensitic stainless steel and austenitic stainless steel. We don't do too much interpretation here. Terada generally uses austenitic stainless steel, and the main processing materials are SS304, SS316 and SS316L. Next we will mainly introduce these three materials.

Stainless Steel 304

304 stainless steel is a common material of stainless steel, a density of 7.93 g / cm³, the industry also called 18/8. High temperature resistance of 800 ℃, with good processing performance and high toughness, widely used in industry and furniture decoration industry and food and medical industry.

Common market labeling method has 06Cr19Ni10, SUS304, which generally represents 06Cr19Ni10 production standard GB, 304 generally indicates ASTM standard production, SUS 304 represents the Japanese standard standard.

304 is a versatile stainless steel, it is widely used in apparatus and parts to produce good overall performance (corrosion resistance and formability). In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 18% chromium and more than 8% nickel. 304 stainless steel is a grade of stainless steel produced in accordance with American ASTM standards.

Stainless Steel 316

By a way, SS316 is more two Mo than SS304, which have a good rust-proof ability and price is higher than SS304.

Stainless Steel 316L

316L is widely used in the chemical industry due to its excellent corrosion resistance. 316L is also a derivative of 18-8 austenitic stainless steel, with 2 to 3% Mo added. Carbon C: ≤0.030, Silicon Si: ≤1.00, Manganese Mn: ≤2.00, Sulfur S: ≤0.030, Phosphorus P: ≤0.045, Chrome Cr: 16.00 ~ 18.00, Nickel Ni: 10.00 ~ 14.00, Molybdenum: 2.00 ~ 3.00 .

Compared to SS316, the carbon content of SS316L is very low, so the rust resistance of SS316L is better than SS316, and the price is higher.

Bronze

Copper materials are divided into brass and red copper, of which red copper is more expensive. Brass is usually represented by H, and the following numbers represent the mass fraction of copper. For example, H68 indicates brass with 68% copper content and 32% zinc content. Copper is distinguished by adding a Z in front of the casting, such as ZH62. For example, Zcuzn38 indicates that the zinc content is 38%, and the rest is copper cast brass.

H90, H80 are single-phase brass, the color is golden yellow, called plating, widely used in decorations, medals, etc.

H68, H59 are duplex brass, widely used in electrical structures, such as bolts, nuts, washers, springs, etc. Generally, single-phase brass for cold deformation processing and dual-phase brass for hot deformation processing.

Red Bronze

H59 Bronze

H62 Bronze

Aluminum & Carbon Steel

Some Products will use aluminum and carbon steel. For carbon steel, we normal use 45# steel and Q235 steel to do forged products.

Aluminum Alloy

45# Steel

Q235

How to choose suitable material?

1. Study Your Drawing and Size

2. Find Suitable Production Way

3. Choose Meet Your Material

Relative Products

SS316

SS304

SS316

SS304

AISI304

AISI316

AISI304

AISI316