Heavy Duty Lifting D Shackle with Screw Pin high-grade materials

Review

Description

Heavy Duty Lifting D Shackle with Screw Pin high-grade materials

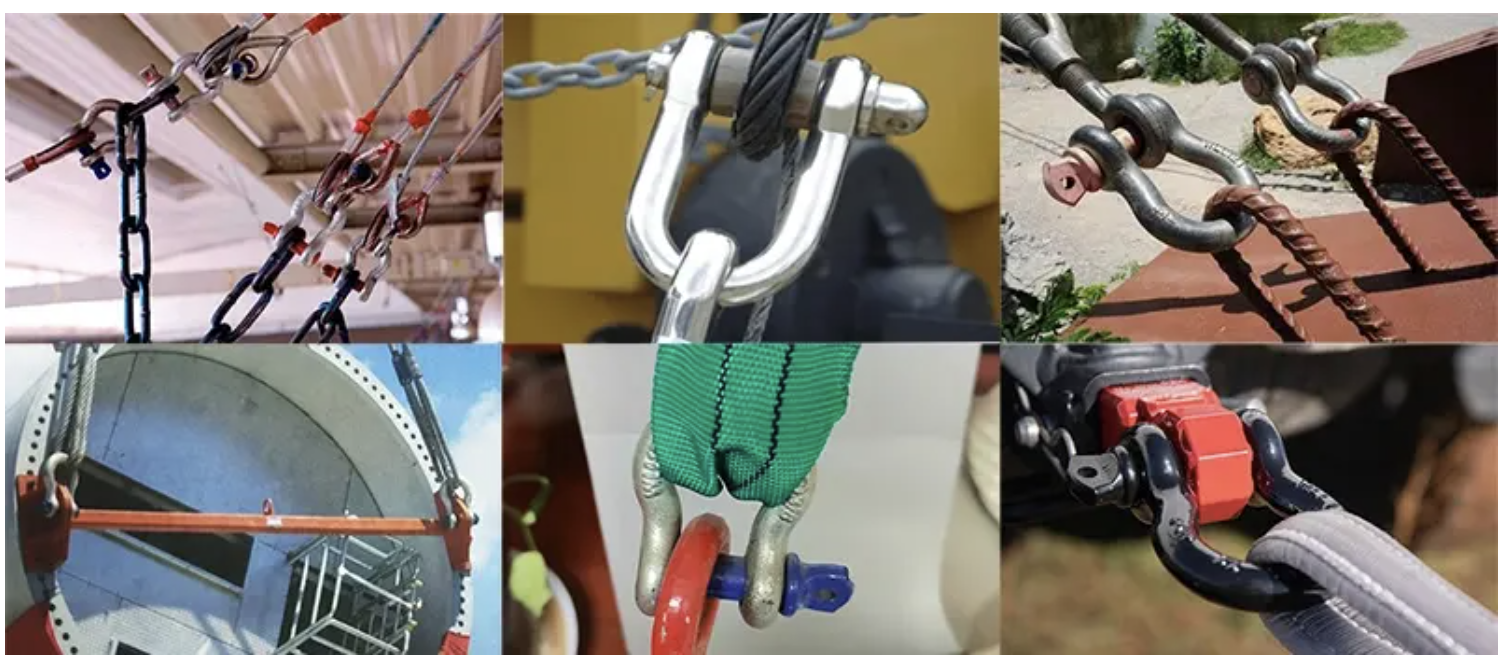

The screw pin shackle is the most ubiquitous type, favored for its simplicity and ease of use. Its pin is threaded and can be easily screwed in and out by hand, making it ideal for applications where frequent connections and disconnections are necessary. However, it is generally recommended for non-permanent, static lifts and should always be properly tightened and checked to prevent loosening from rotation or vibration. For more demanding and critical applications, especially those involving side loads, rotation, or dynamic forces, the bolt-type shackle is the superior choice. This variant features a pin secured with a nut and cotter pin, providing a much more secure and vibration-resistant connection. This positive locking mechanism prevents the pin from accidentally unscrewing, making it essential for lifts where the load could shift or spin.

Beyond these two primary types, specialized shackles exist, such as those made from high-grade stainless steel for exceptional corrosion resistance in marine and chemical environments, or alloy steel shackles that are heat-treated for immense strength. Safety shackles, which feature a built-in bolt collar for added security, are also common.

The material composition is crucial to their performance. High-grade carbon steel or alloy steel are the most prevalent materials, offering an excellent strength-to-weight ratio and are often hot-dip galvanized to provide a durable protective coating against corrosion. For harsh environments, such as offshore marine applications or chemical processing plants, shackles made from 316-grade stainless steel are indispensable due to their superior resistance to rust and pitting.

The proper application of lifting D shackles is paramount to safety. They must never be side-loaded or used if the pin is damaged, as this drastically reduces their safe working load. Regular inspection for signs of wear, cracks, deformation, and thread damage is a non-negotiable practice. Ultimately, these seemingly simple devices are essential tools in construction, manufacturing, shipping, logistics, and entertainment rigging. Their robust design and reliable performance make them the indispensable connecting link that ensures the integrity and safety of the entire lifting operation, safeguarding both personnel and valuable assets.