Why does the stainless steel rigging hardware rust?

- Share

- Issue Time

- Mar 19,2019

Summary

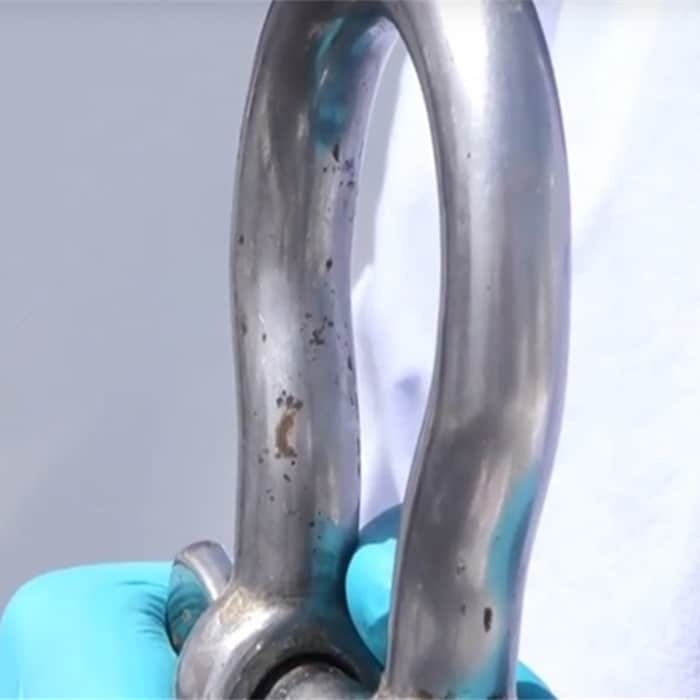

When brown rust spots (dot) appeared on the surface of stainless steel hardware, people were amazed: "Stainless steel is not rusted, rust is not stainless steel, and there may be problems with steel."

Why does the stainless steel rigging rust?

When brown rust spots (dot) appeared on the surface of stainless steel hardware, people were amazed: "Stainless steel is not rusted, rust is not stainless steel, and there may be problems with steel." In fact, this is a one-sided misconception about the lack of understanding of stainless steel. Stainless steel will also rust under certain conditions.

Stainless steel has the ability to resist atmospheric oxidation - that is, rust, and also has the ability to corrode in acids, alkalis, and salts - that is, corrosion resistance. However, the degree of corrosion resistance varies with the chemical composition of the steel itself, the state of addition, the conditions of use, and the type of environmental medium. Such as 304 rigging hardware, in the dry and clean atmosphere, there is absolutely excellent anti-corrosion ability, but it will be moved to the seaside area, in the sea fog containing a lot of salt, it will soon rust; and 316 cable Hardware with good performance. Therefore, it is not any kind of stainless steel that is resistant to corrosion and rust in any environment.

There are many forms of surface film damage, and the following are common in daily life:

Stainless steel is a very thin and strong and stable chromium-rich oxide film (protective film) formed on the surface to prevent the oxygen atoms from continuing to infiltrate and continue to oxidize, thereby obtaining the ability to resist rust. Once for some reason, the film is continually destroyed, oxygen atoms in the air or liquid will continue to infiltrate or iron atoms in the metal will continue to separate out, forming loose iron oxide, and the metal surface will be continuously rusted. There are many forms of such surface film damage, and the following are common in daily life:

1. The surface of the stainless steel contains dust or other metal particles attached to other metal elements. In humid air, the condensed water between the attached material and the stainless steel connects the two into a micro battery, triggering an electrochemical reaction. The protective film is destroyed, which is called electrochemical corrosion.

2. The surface of the stainless steel adheres to the organic juice (such as melon, noodle soup, glutinous rice, etc.), and in the case of water and oxygen, constitutes an organic acid, and the organic acid corrodes the metal surface for a long time.

3. The surface of the stainless steel adheres to acid, alkali and salt substances (such as alkali water and lime water splashing on the wall), causing local corrosion.

4. In polluted air (such as the atmosphere containing a large amount of sulfide, carbon oxide, nitrogen oxide), in the case of condensed water, sulfuric acid, nitric acid, acetic acid liquid point is formed, causing chemical corrosion.

To ensure that the metal surface is permanently bright and not rusted, we recommend:

All of the above can cause the corrosion of the stainless steel surface protective film to cause rust. Therefore, in order to ensure that the metal surface is permanently bright and not rusted, we recommend:

1. The surface of the decorative stainless steel must be cleaned and scrubbed frequently to remove the deposits and eliminate external factors that cause modification.

2. 316 stainless steel is used in the seaside area, and 316 is resistant to seawater corrosion.

3. Some stainless steel chemical components on the market cannot meet the corresponding national standards and cannot meet the requirements of 316 materials. Therefore, it will also cause rust, which requires the user to carefully select the products of reputable manufacturers.