How to Choose the Perfect Wire Rope Clamp?

- Share

- Issue Time

- Jun 1,2022

Summary

Wire rope clamp makes wire rope one of the most versatile rigging hardware. Since these clamps come in different shapes, sizes, and materials.

Wire rope is one of the most critical components in rigging and lifting hardware. You can use wire rope to lift, rig, and tie loads of virtually any size, shape, and type. However, to get the most out of your wire rope, you'll need some additional rigging equipment, one of which includes wire rope clamps.

Also known as wire rope clips, riggers often use this nifty little piece of hardware on the ends of wire ropes. You can use wire rope clips:

Use a lap joint to tie the two wire ropes together.

Create a load-bearing eye on the end of the wire rope by bending the end of the same wire back.

In short, wire rope clamps make wire rope one of the most versatile rigging hardware. Since these clamps come in different shapes, sizes and materials, you need to choose a clamp that is perfectly suited to your lifting and rigging application. But before we start, first, you need to understand what a wire rope clamp is, its type, and a few other things.

What is a wire rope clamp?

It is a simple mechanical device. A typical wire rope clamp consists of a saddle, U-bolt, and two hex nuts. This simple device is suitable for less permanent rigging and lifting applications. Never use wire rope clips to make industrial slings.

Riggers should not use mechanical wire rope terminations that require periodic adjustments to make slings. In other words, you need to be careful when using rope clips. You can use wire rope clips to create end loops for winch or crane cables. You can also use it to build perimeter cables or increase wire rope lengths through D-shackles or eyebolts.

Fixture type

Depending on their shape, there are two types of cable clamps, U-bolt and double saddle. They all have unique mechanical properties and applications.

1. Traditional U-bolt wire rope clamp

These cable clamps consist of a U-bolt, two nuts, and a metal base called a saddle. The U-bold goes through the saddle and you can tighten it with two nuts. They come in a variety of sizes and types of materials, including stainless and galvanized steel. You can choose U-bolt wire rope clamps according to your rigging or lifting application.

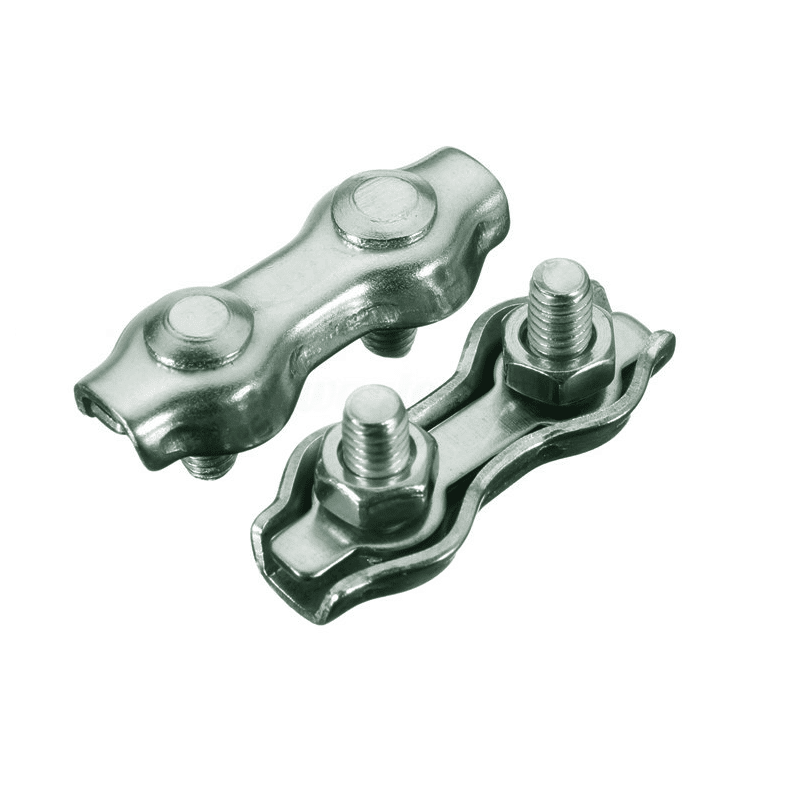

2. Double saddle wire rope clamp

These rackets consist of two saddles, each with a leg and two nuts. Since the saddles are mirrored, they can be mounted to each other without bolts. This unique design also means you can use them in either orientation, which makes them more user-friendly.

Materials from which wire rope clamps are made

Generally, there are three materials used to make rope clips. You can choose a material based on your application, as each material has its own unique strengths and weaknesses.

1. Drop forged galvanized

In this type of wire rope clamp, the base or saddle is made of forged steel. The manufacturing process involves heating and hammering the clips into the desired shape. Cranes often use these cable clamps for critical and heavy-duty applications because they are so sturdy. You can see them in winch wires, crane cables, hoist wires, tow wires, scaffolding, guy wires, and even tie downs.

Properties of drop forged galvanized U-bolt wire rope clamps

They cost less than stainless steel wire rope clamps.

They are more suitable for outdoor environments.

However, they are not as corrosion-resistant as stainless steel variants.

2. Forged galvanized

The base or saddle is made of cast iron. Since cast iron lacks the metallic properties of stainless steel, it is not strong. Therefore, malleable galvanized wire rope clamps are not very strong. They can crack with heavy use. You will see them being used in small or light-duty applications such as fencing, parametric cables, or guardrails.

Characteristics of malleable galvanized wire rope clamps

They can be used in outdoor environments.

But they are not as corrosion resistant as other types of wire rope clamps.

Their surfaces quickly rust when exposed to rain, snow, salty air, or salt water.

3. Stainless steel

Stainless steel wire rope clamps are arguably the best. The base or saddle is made of high tensile strength stainless steel. They are durable and easy to use. You can find these cable clips in temporary fences, flagpoles, and other outdoor rigging applications.

The performance of stainless steel wire rope clamp

These are the most corrosion-resistant wire rope clamps.

Even in salt water environments, they have strong surface rust resistance and are best suited for outdoor environments.

Since stainless steel is expensive, they are a bit expensive compared to other types of clamps.

In summary

Wire rope clips are one of the essential rigging hardware. They make the wire rope more flexible, allowing you to handle a variety of applications easily and safely. These tips will help you choose the right clamp for your needs. If you have questions or want to buy wire ropes and accessories, please contact us.

Terada Hardware is a professional custom wire ropes and accessories manufacturer. Our role goes beyond designers and manufacturers. We treat our customers as part of the team and support them as partners. For non-standard hardware. We listen carefully to customers' requirements and provide some professional advice and technical support. Follow the new designs to make the most suitable hardware for your project.