How is Wire Rope Made?

- Share

- Issue Time

- Mar 29,2022

Summary

Wire ropes are more and more used in our lives, so do you know how wire ropes are made? Let's briefly introduce the basic composition of the wire rope and its name.

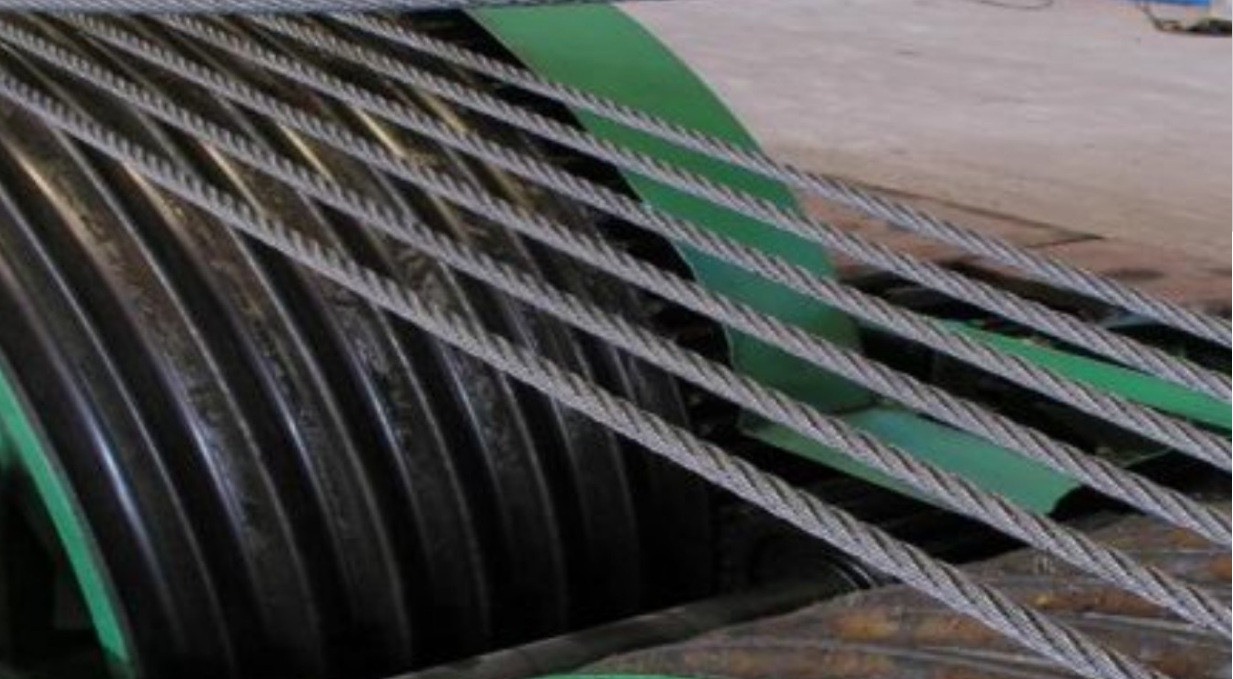

The term wire rope includes a variety of machine tools used to perform heavy and extreme lifting work. A wire rope is a complex and complex tool with multiple moving parts that allow for coordinated movements. A 6 x 25 wire rope has 150 outer strands that move as a unit in a complex pattern supported by a flexible core.

An important part of the wire rope design is the required clearance between the strands to allow each bracket to move and adjust freely as the rope bends. It is this unique characteristic that differentiates wire rope from solid wire and other forms of cable.

Wire Rope Manufacturing

The three basic components of a wire rope are steel wire, strands, and core wire, which are twisted together to form the rope.

Metallic line

The basic element of a wire rope is the wire used to configure, shape, and form the rope. Generally, steel, stainless steel, and galvanized wire is preferred, followed by aluminum, nickel alloys, bronze, copper, and titanium. The choice of wire depends on the type of work the wire will be used for, with strength, flexibility, and wear resistance being the main determinants.

Galvanized steel

Galvanized steel is coated with zinc to prevent corrosion and is an affordable alternative to stainless steel.

Stainless steel

Stainless steel wire rope has all the essential qualities of galvanized wire rope and regular wire rope with the added benefit of being resistant to corrosion and rust; this makes it ideal for harsh and stressful conditions.

Steel

Wire ropes are classified as general-purpose wire ropes and come in a variety of sizes, diameters, and strengths. It is the most common type of wire rope and is used in a variety of industrial, manufacturing, and construction applications.

Wire Rope Identification and Naming

Before discussing further how wire ropes are made, it is important to understand the numbers used to describe each type. All wire ropes have a core wire around which the wire is wound. Depending on the required construction and design of the wire rope to be produced, the various types of core wire will vary.

Wire ropes are classified by the number of strands and the number of wires in each strand. The most common assortment is seven-wire ropes with one strand in the center and six strands around. This wire rope is light in weight and very simple in structure. Most wire ropes are more complex and intricate, with multiple intertwined strands and wires.

What must be understood about wire rope is that it has a complex configuration. It's actually wires wrapped around wires to form bundles, which are then wrapped around other bundles. In the case of a seven-core wire rope, bundles of wire are wound around the core;

Strands

The first step in wire rope production is the production of wire rope in which the wire is wound around a single core wire. The number of wires contained in a strand depends on the specified strength, flexibility, and size requirements of the rope. Once the stranding is complete, straighten it before moving to wire rope construction.

Strand pattern

Like wire rope, the strands have different patterns; the pattern is the arrangement of the wires and their diameters. Although most strands have a core, there are also three or four-strand patterns without a core called a centerless strand. Each strand pattern is designed to strengthen the rope and improve its performance.

Coreless stranded wire

All wires of stranded wires are the same size and are twisted together to form a spiral.

Single-layer

The single-layer stranded wire goes a step further than centerless mode, with one core and multiple wires wound around a circumference.

Each wire has the same diameter as the centerless pattern.

Multilayer

For multi-layer stranded wire, the conductor layers are stacked on top of each other in a continuous sequence. The wires must be placed on top of each other so that they fit smoothly and evenly.

Wire rope laying

Core selection and strand creation are the simplest but most important parts of wire rope construction. Wire rope laying, the method used to wrap the strands, is more complicated and involves a variety of options.

Lay is a term used to describe three main characteristics of wire rope: orientation, relationship, and linear distance. The strands can be wound on the core to the right or left. Right or left refers to the orientation of the strands wrapped around the core and the wires within the strands. Linear distance is the distance the wire travels as it rotates around the core.

Laying Type

Common

In a regular lay, the wires and strands spiral in opposite directions. In the case of a right-handed conventional lay, the wire is spiraled to the left and the strands are spiraled to the right. In a left-handed regular layout, the wires are spiraled to the right and the strands are spiraled to the left. This type of layup is easy to handle but wears out quickly because the crown wires come into contact with the bearing surfaces.

Long

In Lang or Albert laying, the wires and strands are spiraled in the same direction, with right-hand laying being the most common. The wire in the Lang appears to be parallel to the centerline of the rope. The difficulty with Lang laying wire ropes is handling, as they tend to kink, twist and squeeze.

Spare

Alternate laying is a combination of conventional laying and Lang laying; this is for specialized applications only.

Hope the above can help you know more about steel wire rope, if you need it, please contact us.

Terada Hardware is a professional wire rope fittings supplier. Focus on creating and protecting value. We offer a full range of hardware. Our accessories are widely used in shading structures, tensile structures, fabric stretching, wire railings, railing systems, railing systems, marine, lifting, and other industries. The industry has accumulated many years of manufacturing experience, strong technical force, mature production technology, sophisticated equipment, and complete testing methods. Our role goes beyond designers and manufacturers. We treat our customers as part of the team and support them as partners. For non-standard hardware. We listen carefully to customers' requirements and provide some professional advice and technical support. Follow the new designs to make the most suitable hardware for your project.