How to Check the Crane Wire Rope?

- Share

- Issue Time

- Jan 14,2022

Summary

This article has sorted out some matters for checking crane wire ropes for everyone, hoping to give you some reference opinions.

The inspection of the crane wire rope is an essential work, which will check the structural performance of the wire rope. The following has sorted out the matters for checking the crane wire rope for your reference.

1. The crane wire rope should be checked at least once a week, and other operating wire ropes should be checked at least once a month. The wire rope status report should be filled out in detail, dated and signed, and loaded into the equipment file for future reference.

2. When the small crane is parked or stored when all the wire ropes are idle for one month or more, they should be thoroughly inspected before being reused.

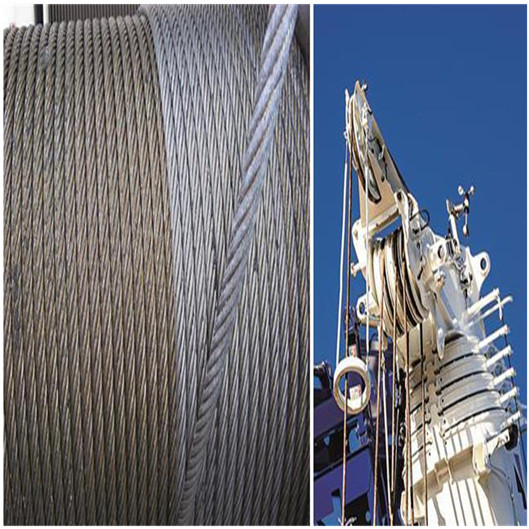

3. The hoisting mechanism should use multi-strand non-rotating wire ropes, and there should be devices or measures to prevent the wire ropes from twisting during the working process, and long braided wire ropes should not be used.

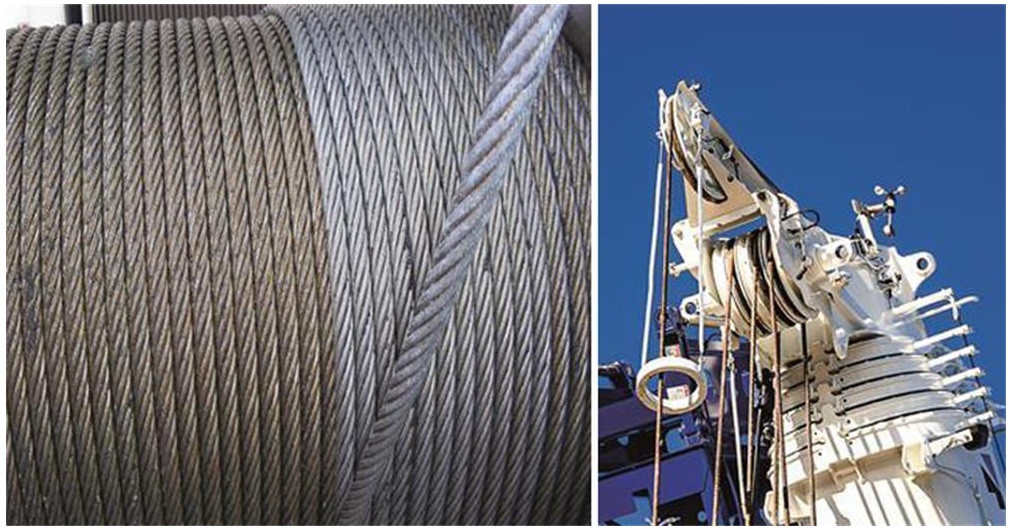

4. The steel wire ropes should be neatly arranged on the reel, and should not be skipped or wound. The end of the drum should be firmly fixed, and the safety circle of the drum should not be less than two circles when the hook is at the lowest position.

5. When connecting with rope clips, the connection strength should be guaranteed to be no less than 85% of the breaking tension of the wire rope, and the distance between the rope clips should not be less than 6 times the diameter of the wire rope. The rope clamping plate should be placed on the long side of the wire rope, and the wire rope should be pressed by one-third. It is strictly forbidden to install the front and back sides staggered.

5. In order to ensure safety, when the number of broken wires in the inner and outer layers of the wire rope reaches a certain percentage of the number of broken wires, the wire rope should be scrapped. If the steel wire rope is detected and scrapped, each thick steel wire shall be calculated according to 1.7. When one strand is broken, it should be scrapped. When the outer wire diameter wear reaches 40% or the wire rope diameter wear reduces to 15%, it should be scrapped.

(1) When the wire rope is clamped, it shall comply with the provisions of GB/T 5976, and its bonding strength shall not be less than 85% of the breaking tension of the wire rope.

(2) When weaving and inserting, the length of weaving and inserting shall not be less than 20 times the diameter of the wire rope, and shall not be less than 30mm, and the strength of weaving and inserting shall not be less than 75% of the breaking tension of the wire rope.

(3) When the wedge and wedge sleeve is fixed, the wedge and wedge sleeve shall comply with the provisions of GB/T 5973, and the bonding strength shall not be less than 75% of the braking force of the wire rope.

(4) The aluminum alloy casing, steel casing, and wire rope should be firmly bonded by reliable process methods, and the bonding strength should reach 90% of the breaking tension of the wire rope.

If you want to know more about wire rope after reading the above, we are happy to share our professional knowledge with you. You can also continue to pay attention to our news, we will update in time.

With excellent manufacturing technology and leading production technology, TERADA has quickly become a leader in the hardware supply industry. We are equipped with a professional quality inspection system, which can control the quality of our products in an all-around way. At the same time, we will also customize professional solutions according to the diverse needs of users. If you want to buy our wire rope, please contact us immediately!