What is a Wire Rope?

- Share

- Issue Time

- Sep 24,2021

Summary

Wire rope has a wide range of applications in the lifting rigging industry. Today, let’s take a look at the relevant knowledge of wire rope.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles, or hooks to attach to a load and move it in a controlled matter.

It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers. Through the following advantages and structure of wire ropes, we can learn better about them.

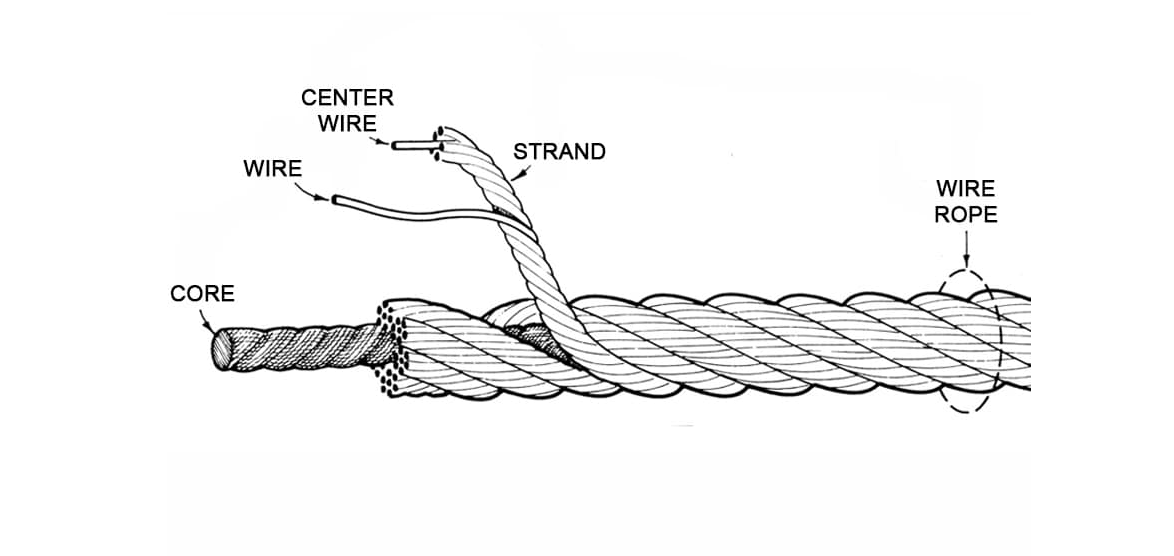

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses.

Wire ropes will provide different benefits for the specific lifting application, including:

(1) Strength

(2) Flexibility

(3) Abrasion resistance

(4) Crushing resistance

(5) Fatigue resistance

(6) Corrosion resistance

(7) Rotation resistance

A typical 6 x 25 rope has 150 wires in the outer strands. When the rope is bent, all the wires move independently and move around the core in a very complicated pattern.

When the rope is designed with a suitable bearing clearance, the clearance between the steel wire and the strand is balanced to allow the internal movement and adjustment of the steel wire and the strand when the rope must be bent. These gaps will change with bending but are the same as the gap range in automotive engine bearings.

Components of Wire Rope

Wire

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, Monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

The wires themselves can be coated but are most commonly available in a “bright” or uncoated finish.

Strands

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

Strands made of larger diameter wires are more resistant to abrasion, while strands made of smaller diameter wires are more flexible.

Core

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

The steel wire rope manufactured by TERADA has excellent performance, and there are many types to meet different engineering needs. If you want to know more about wire rope after reading the above, you can get a comprehensive solution by contacting us.

With excellent production technology and high-quality service, we have quickly become one of the leading hardware suppliers. Our excellent technology and comprehensive quality control system can provide customers with high-quality and safe products. At the same time, we will provide thoughtful one-stop service and effective solution technology according to the diverse needs of customers. If you are interested in our wire rope, please contact us immediately!