White Aircraft Cable 12mm PVC Coated Aircraft Cable Hot Galvanized for Tensile Structure or Shade sail

- Model

- TRD-719WR

Item specifics

- Material

- Marine Grade 304 or 316, stainless steel

- Process

- CNC machining,Casting,Stamping,Hot forging

- Requirements

- Good quality material, high surface, no rust

- Package

- Thickened Woven Bag,Five Ply Cartons, Pallets

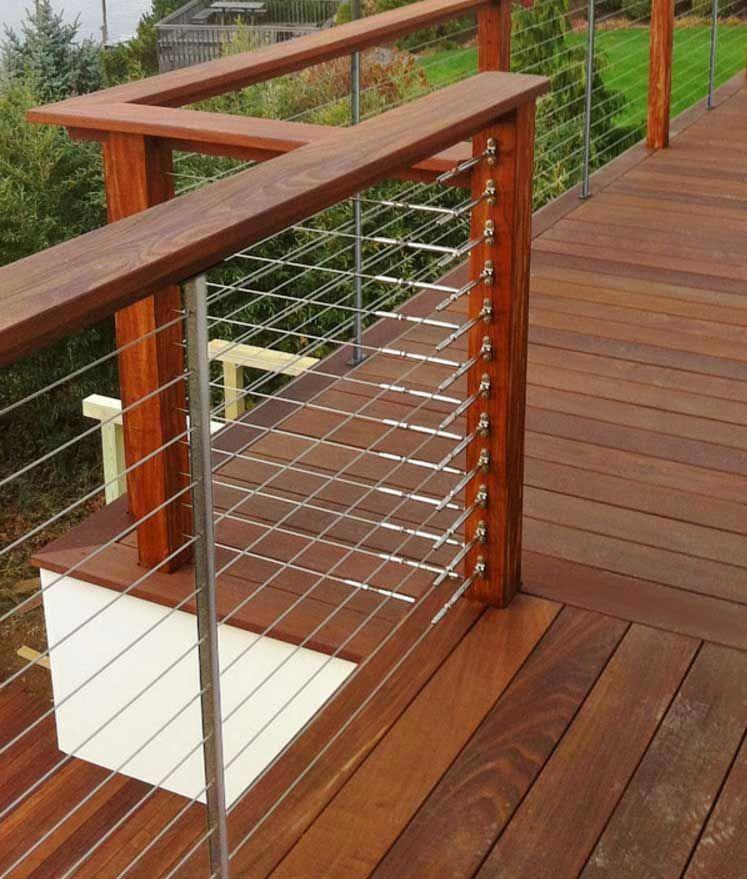

- Application

- Wire Rope, Tensile Structure, Lifting

- Relative Hardware

- US Type Turnbuckle, JIS Turnbuckle, Toggle Turnbuckle

Review

Description

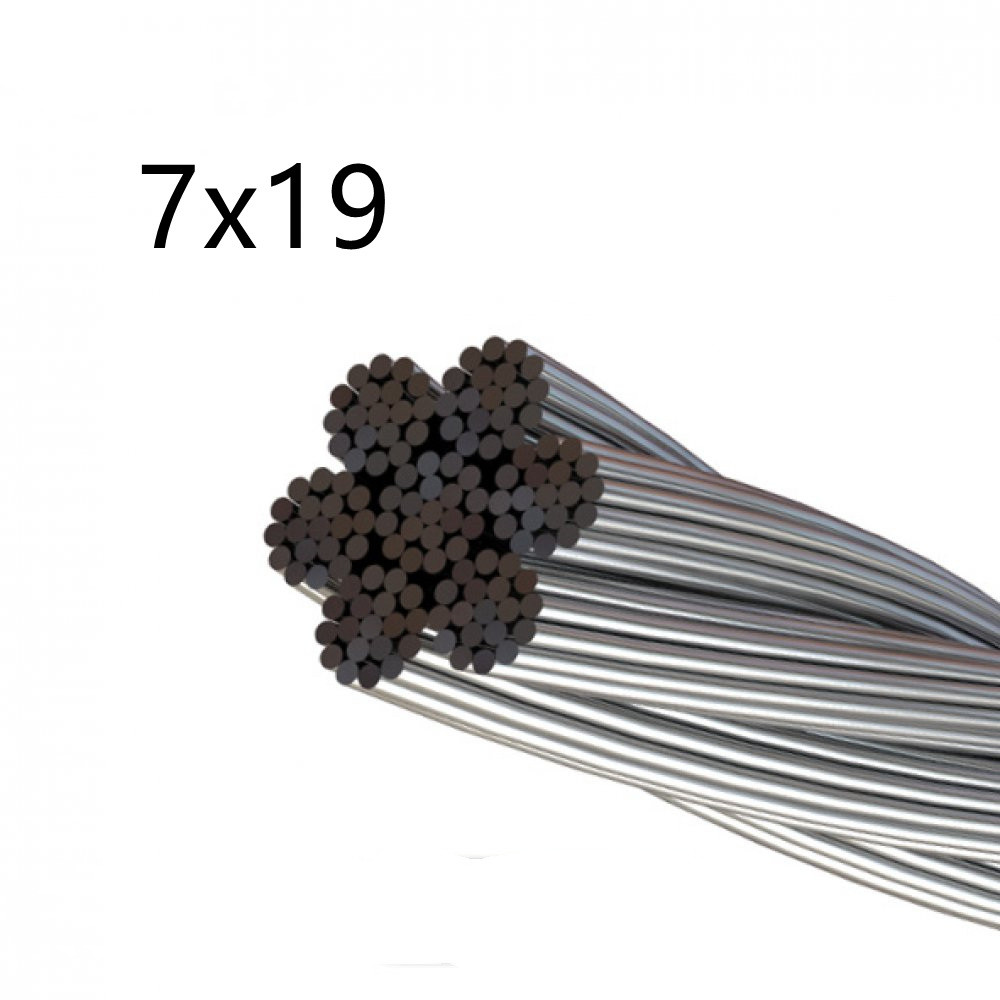

Hot Galvanized 7x19 Wire Rope Aircraft Wire Cable

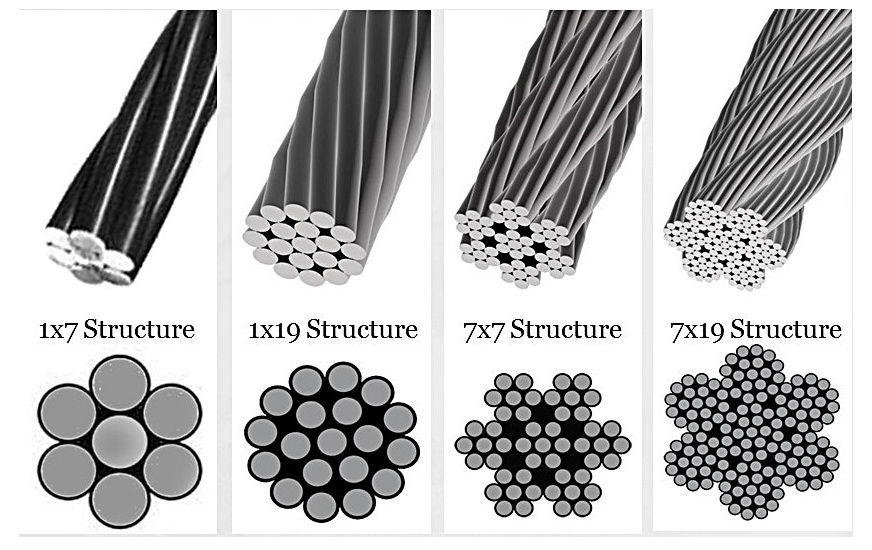

The steel wire rope expression is 7*19, which means that the steel wire rope has 7 strands, 7 means the number of strands, each strand has 19 steel wires, point-contact strand structure, this structure is a steel core wire rope, which can also be expressed as 6*19+IWS, these two expressions are actually a kind of steel wire rope structure.

Steel wire ropes and steel strands are made of twisted steel wires. The structure of the steel strands is simple, with only 1*7, 1*19 and 7*7 structures. The lay length of the steel strand is generally 14 times, and the lay length of the steel wire is average. No more than 8 times, the surface of the steel wire rope is coated with grease, and the steel strand is not coated or coated with anti-rust grease. There are nearly a hundred types of steel wire rope structures, far more than that of steel strands.

Wire rope quality judgment:

1. Specific gravity. The diameter of the wire rope is the same, the heavier the specific gravity, the better the quality of the wire rope.

2. Steel wire rope core. The stronger the steel wire rope core, the heavier the specific gravity, the better the supporting force for the outer strands of the steel wire rope, and the better the quality of the steel wire rope.

3. Materials. The material is steel grade and strong. The higher the steel grade, the higher the strength of the steel wire rope, the better the quality.

4. After the rope is cut, the slightly loose quality is good, and the quality of the wire rope with a relatively long lay length is better than that with a short lay length.

5. The anti-corrosion ability of 316 stainless steel wire rope is stronger than that of 304 stainless steel wire rope, and the anti-corrosion ability of 304 stainless steel wire rope is stronger than that of hot-dip galvanized steel wire rope. Hot-dip galvanizing is better than electro-galvanized steel wire rope; the quality of nylon plastic-coated steel wire rope is stronger than that of PE plastic-coated steel wire rope.

Material

l Stainless Steel 316 ( AISI316) l Stainless Steel 304 ( AISI304)

l Stainless Steel316L l Carbon Steel

Surface Treatment

l Plain Surface l Hand Mirror Polished

l Galvanized or Hot Galvanized l Paint Spraying

Process

l CNC Processing l Precision Casting

l Hot Forged l Stamping

Application

PS: ODM Order and Non-Standard products also could made and designed by Terada Team, Welcome to Contact us.